The Original action inside the freeze-drying process is managed freezing, a action whose worth can not be overstated. This period serves as being the groundwork for the subsequent drying levels, figuring out the size and framework from the ice crystals formed.

Is your Labconco solution operating effectively? Solution Service is ready to help with set up thoughts, troubleshooting and substitution parts to your present Labconco products.

Areas of focus include analytical and formulation issues, process checking and Manage, as well as submit-lyophilization analysis. Written to the Strategies in Pharmacology and Toxicology sequence, chapters include things like the kind of pro assistance that results in exceptional brings about the lab.

The process of lyophilization, or even the freeze-drying of pharmaceutical products together with biologics/Organic products, has become Utilized in the foods and pharmaceutical products such as biologics/Organic products, has become used in the foods and pharmaceutical industries to preserve and stabilize medications For the reason that 1940’s.

Below we aimed to supply exact, comprehensive lyophilization protocols for animal tissues along with other Organic supplies for laboratory investigate use and for scientific application at the same time.

That's for the reason that lyophilization delivers with it several worries: It's expensive. It provides a lot more time and energy to the process.

Launch the stress quite slowly and gradually and carefully at the end of lyophilization by opening the valves gradually one by one to forestall more substantial airwaves blowing absent small sample pieces and spilling ice condensates on to the dry samples.

Acquire these methods to arrange get more info your new FreeZone Freeze Dryer Console. The online video involves Guidance for installing a multi-port manifold or a chamber with valve ports.

Lyophilization and homogenization of Organic samples improves reproducibility and lessens standard deviation in molecular biology methods

Formulation also impacts the benefit of reconstituting the lyophilized powder again into a solution for administration—a well-formulated lyophilized merchandise will dissolve rapidly and simply with no leaving particulates or resulting in adjustments from the drug’s potency—and it impacts the extended-term security in the lyophilized merchandise.

The final result? A secure, dry powder which can be reconstituted to its primary form when necessary, all whilst sustaining its first potency and efficacy.

Because Every single solution is different, Each individual lyophilization process involves various temperatures and recipes, this means that each merchandise has to be intensely investigated and documented to make sure what is a lyophilization process usable results. A person last threat is always that lyophilization provides a substantial contamination hazard as a result of product remaining exposed for prolonged durations of time2.

The protocols Within this review were being established on a ScanVac CoolSafe Touch Top-quality instrument manufactured by LaboGene A/S, Allerod, Denmark; but specified the generality of actual Bodily parameters, extremely very similar ways may very well be relevant for other freeze dryer products too (Pisano et al.

For most products, particularly in the pharmaceutical sector, even the slightest fluctuation in moisture ranges may lead to degradation, loss of efficacy, or the development of undesirable

James Van Der Beek Then & Now!

James Van Der Beek Then & Now! Nancy Kerrigan Then & Now!

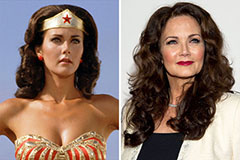

Nancy Kerrigan Then & Now! Lynda Carter Then & Now!

Lynda Carter Then & Now! Bill Cosby Then & Now!

Bill Cosby Then & Now! Catherine Bach Then & Now!

Catherine Bach Then & Now!